Les Cobots Rainbow minimisent le temps de production et maximisent l'efficacité en gérant les tâches récurrentes et de routine.

Robot Specifications

WHY RB SERIES?

Robust Aluminum Construction

Our cobots' aluminum bodies are ideal for polishing, processing, and welding. With the durable and light hardware, robot can perform reliably in tough manufacturing environments.

Industry-leading IP Rating

RB Series Cobots offer best-in-class IP ratings (IP66).

Cobots can take on more diverse roles at CNC machining sites, food and beverage sites, etc.

Versatile built-in Features

RB Series offers numerous built-in features. Immediately deploy RB Cobot into various

applications without additional programming or costs.

Certified & Tested

All our cobots undergo rigorous testing and are certified by TÜV SÜD for its safety and performance reliability to meet global standards:

- ISO 1349-1, Cat.3, PL d

- ISO 10218-1

- ISO/TS 15066

- NSF/ANSI 169

- NRTL(UL 1740), CSA(Z434)

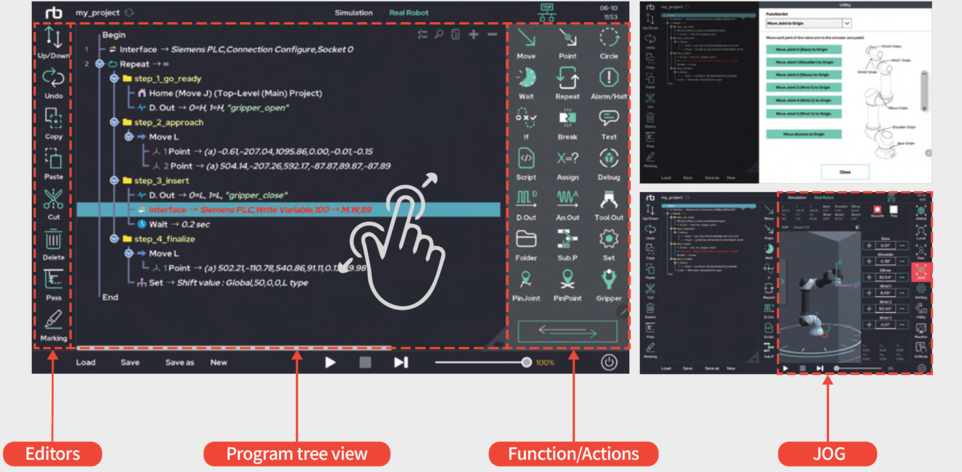

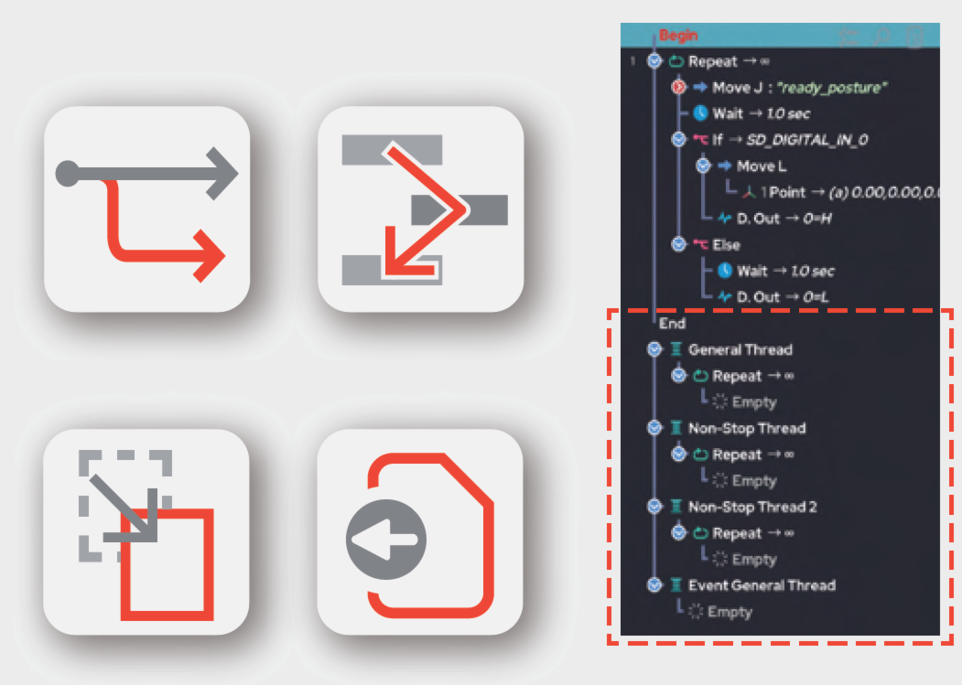

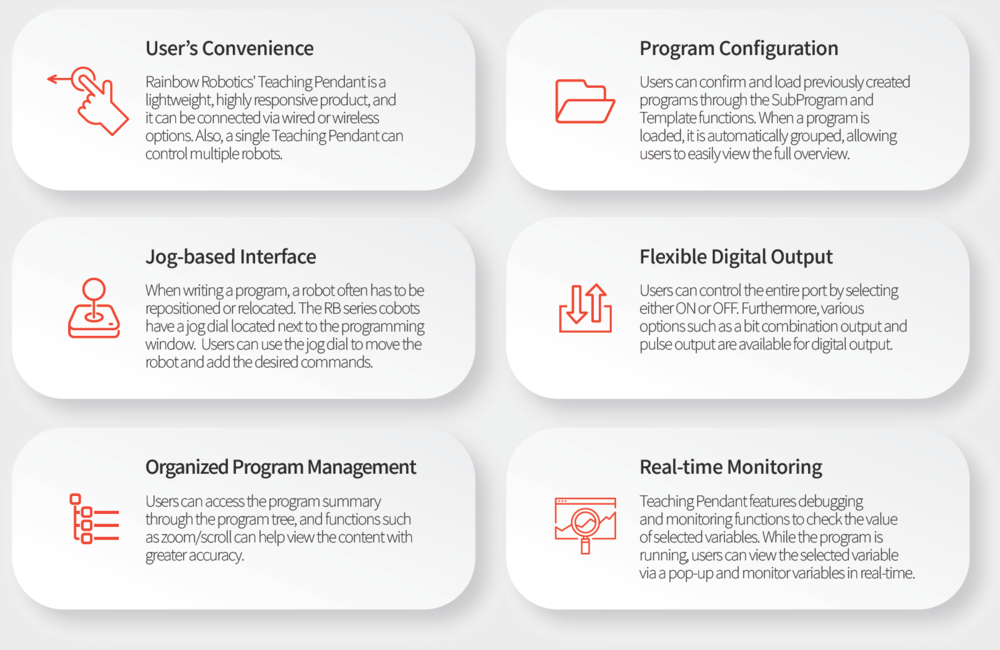

Convenient Program View

Rainbow Robotics provides an intuitive and progressive proprietary UI. Deploy your automation project with just a few clicks through the touch screen / monitor. Convenient program creation increases your productivity and reduces the time and cost required for program management.

By utilizing industry-leading built-in functions, RB series robots can be quickly deployed into automation sites without additional costs.

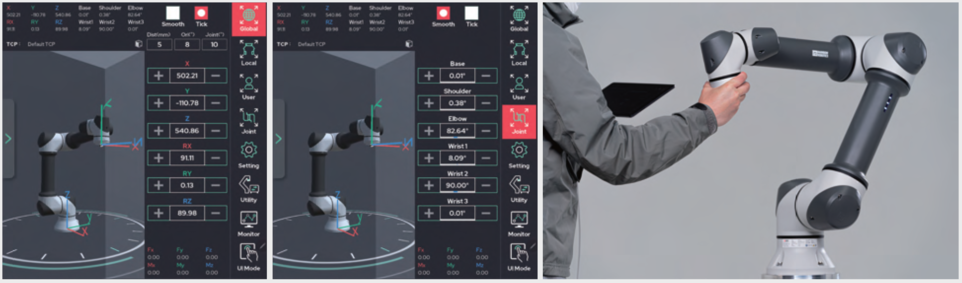

Versatile Jog

User can manipulate the robot arm based on various coordinate systems.

Robot moves based on the coordinate system selected by the user. By using Tick Mode, user can adjust the interval as desired.

User can also operate the robot using the Hand-Guiding (Free-Drive) function through the button attached to the end of the robot.

Experience advanced hand-guiding function that moves the robot arm by constraining specific plane or direction.

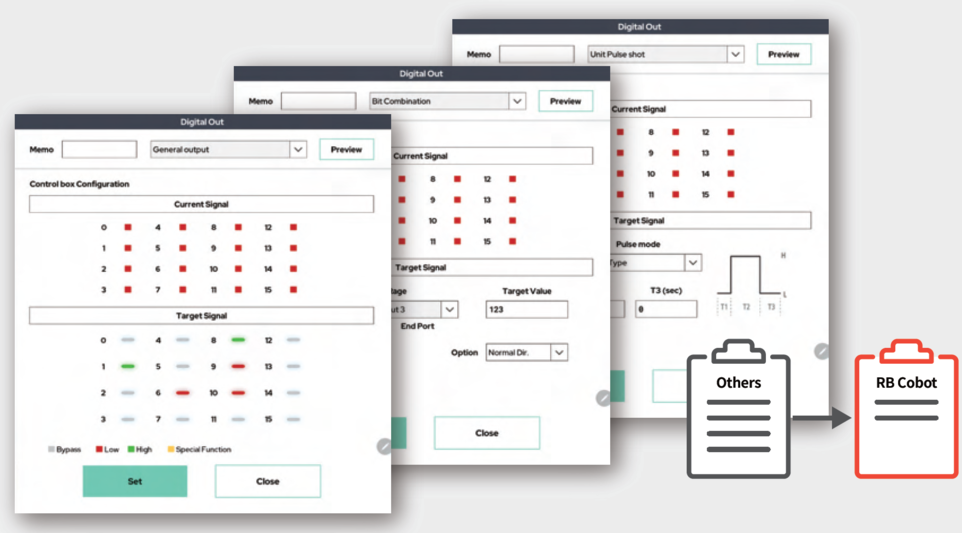

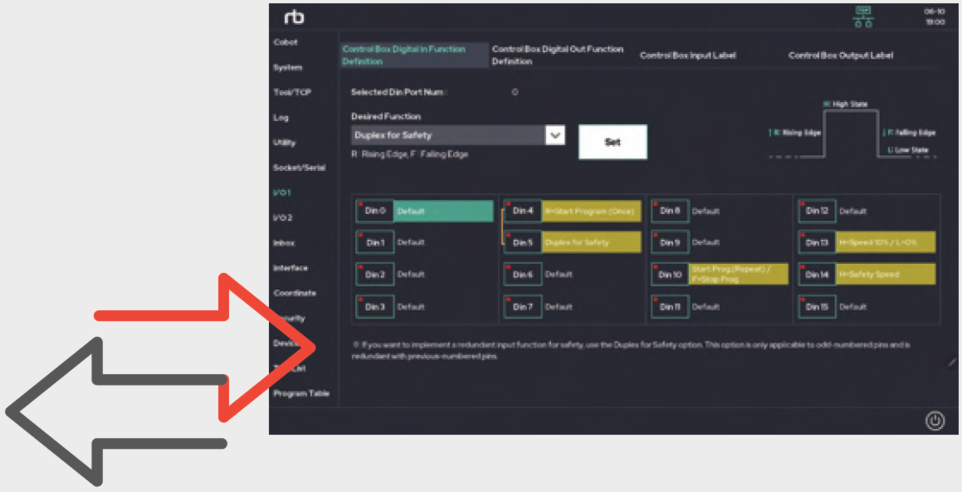

Easy I/O Management

RB Series provide a variety of options for controlling the most frequently used input/output signals in the field.

It provides various options such as simple output, pulse output, bit combination output, and delayed output, allowing you to control signals without separate coding.

Multi-Processing

To cope with various automation sites, one main program pipeline and four parallel pipelines are provided. In addition, it provides a program management tools such as [SubProgram], [ProgramConvert], [Template], allowing you to manage projects efficiently and safely.

- Thread

- Event Thread

- Sub Program

- Template

- Program Conversion

Configurable System I/O

To ensure a smooth system configuration with PLC and peripheral devices, there are over 100 various system management I/O functions.

Designated functions are performed and managed in the background without separate programming.

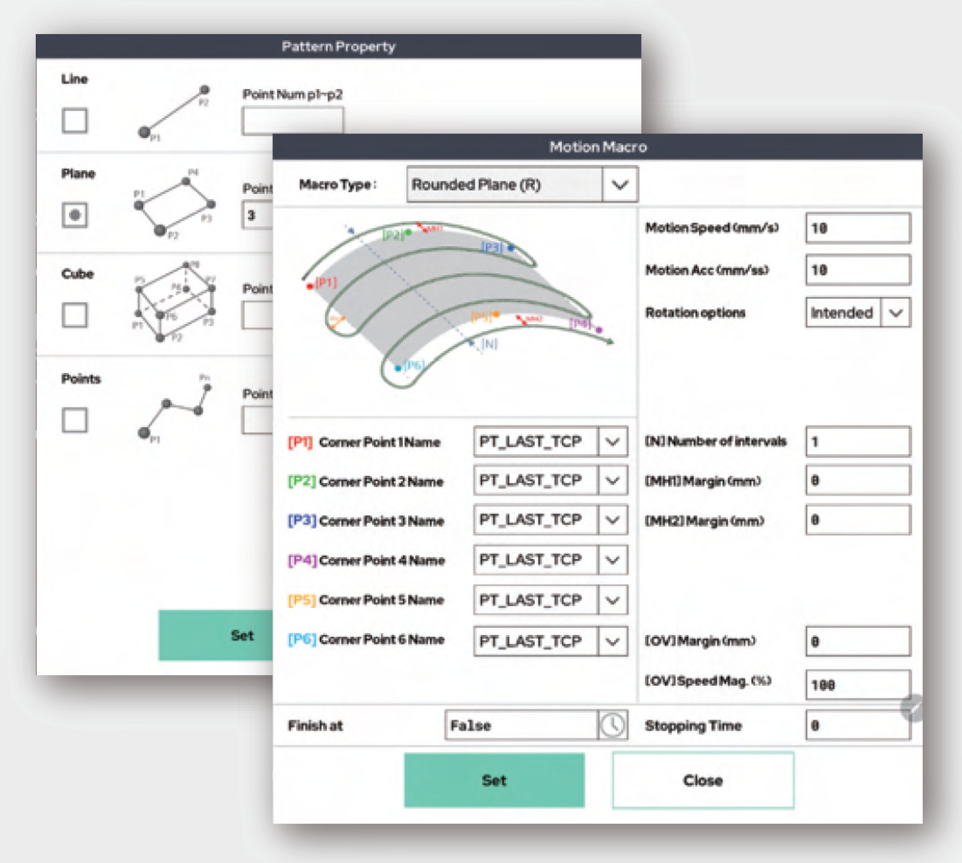

Polishing & Grinding

Users are free from harsh polishing/painting environments. Using Rainbow's features, you can easily implement repeated actions. We provide the best solution for creating repetitive and patterned robot trajectories such as polishing/painting.

By using functions such as [Motion macros] and [Pattern], users are free from repeated robot teaching. Even if the object changes, user can respond quickly by just changing few landmark points. Don't waste any more time teaching repetitive movements.

Intelligent Force control

Rainbow Robotics’ collaborative robots feature a built-in force control function. User can easily implement force control by connecting them to various Force/Torque sensors (Hardware is add-on option). RB cobots are capable of performing surface treatments such as grinding and polishing with constant force.

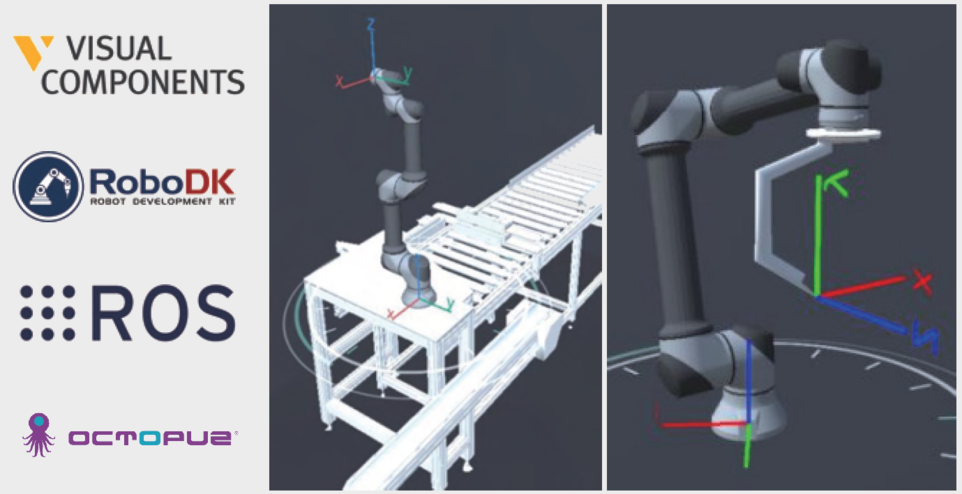

Easy 3D Modeling Simulation

Users can load a 3D modeling file designed for the project environment into the UI and virtually review the robot's path and workability.

In addition, Rainbow Robotics also supports Third Party OLPs, such as RoboDK, Visual Components, Octopuz, ROS.

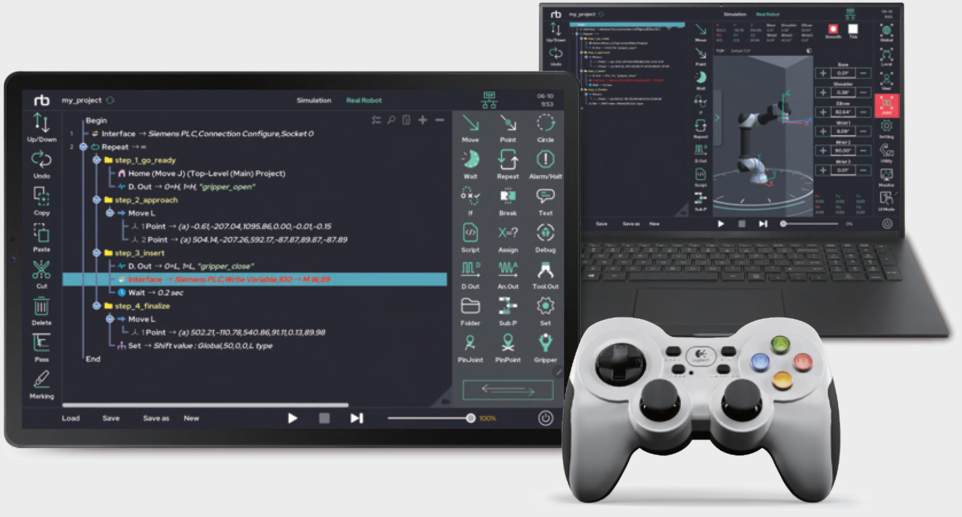

Teaching Pendant

Rainbow Robotics’ cobots are easy to program using the Rainbow Robotics Teaching Pendant. Moreover, the icon-based GUI allows users to configure the interface to suit their required conditions. The user-friendly GUI also makes maintenance easier, improves security, and enables intuitive programming. Teaching Pendant is compatible with Android OS-based smartphones, tablet PCs, and Windows OS-based devices.

Main Features

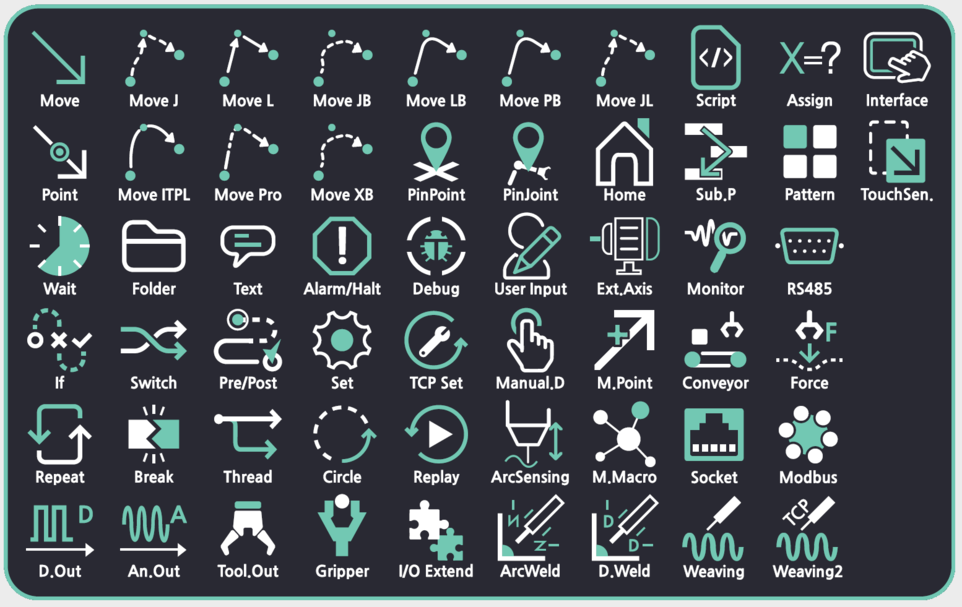

Built-In Functionality

Rainbow Robotics' RB Series has various built-in functions for users. Experience a variety of motion creation functions, communication functions, and program management functions without installation and extra cost.

- Robot Arm Movement: Move J, Move L, Move JB, Move LB, Move PB, Move JL, Move ITPL, Move Pro, Move XB, Circle, Home

- Program Logic Flow: Wait, if/else, Repeat, Break, Continue, Switch, Halt, Jump, Pre-Program, Post-Program, Thread, Sub-Program, Convert

- User Programming: Assign, Script, Debug, Monitoring, Memo, Alarm, User Input, User Log, Folder

- Advanced Motion Generation: Pattern, Weaving, TCP-Weaving, Conveyor, Force-Control, Motion Macro, RePlay, G-Code, Pin-Point, Pin-Joint

- Welding Application: ArcWelder On/Off, Digital Welder On/Off, ArcSensing, TouchSensing

- I/O Control Function: Digital Out, Analog Out, Extention I/O Control, Tool-Flange Out, Gripper

- Communication: Interface, TCP/IP Socket, Serial, Modbus, EtherNet/IP, ProfiNet, OPC-UA

- Others: Set, TCP-Set, Manual Driving, External Axis

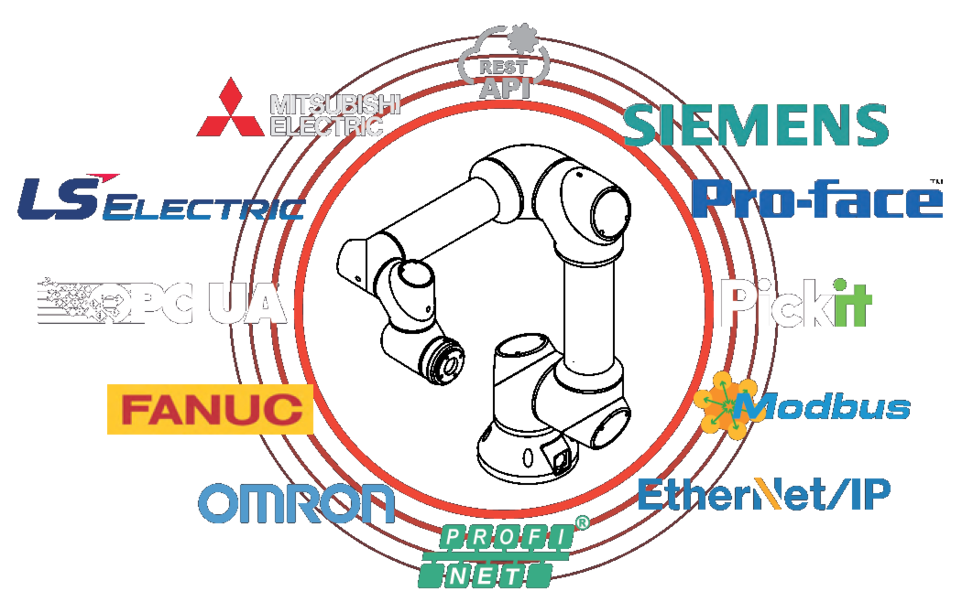

Infinite Connectivity

Communication with various equipment is required in automation sites. Using Rainbow collaborative robots, you can easily communicate with various parallels such as PLC, HMI, and sensors.

- International standards: ModbusTCP, EtherNet/IP, ProfiNet, OPC-UA

- Manufacturer designated: FINS (OMRON), S7 (Siemens), MC (Mitsubishi), XGT (LS), MemoryLink (Proface HMI), Focas (FANUC)

- General: TCP/IP Socket, RS232/485

* The intellectual property rights for the product images and logos used in this promotional material belong to the respective manufacturers.

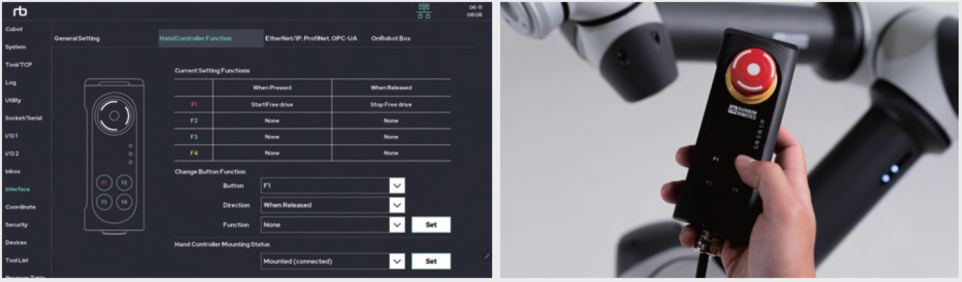

Customizable Hand Controller

RB Series collaborative robots come with a hand controller. User can use it by setting the desired function to the function keys of the hand controller.

Increase the usability of the collaborative robot through the buttons on the hand controller without making separate buttons.

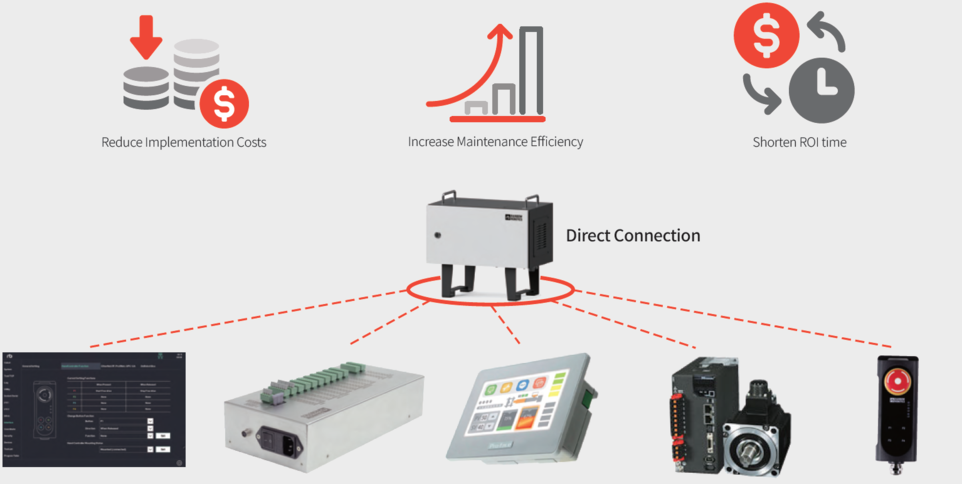

Achieve your automation without PLC

RB Series provides various features and functions for automation without PLC.

Implement simple and light automation using only RB Cobot.

- Software PLC: A simple PLC ladder can be implemented in the robot control box. You can process various input/output signals and communication signals through Software PLC Ladder.

- HMI Communication: MemoryLink communication is available for HMI devices such as ProFace and M2I. Connect the customer’s preferred HMI directly to the robot.

- I/O Extention: There is a dedicated I/O expansion module, so you can increase the number of I/O through plug and play.

- AC ServoMotor Control: AC Servo Motor can be controlled by a robot without a PLC. Immediately implement horizontal rails, vertical elevators, etc.

- FANUC Communication: Supports digital communication to exchange data with FANUC CNC machines. You can easily configure CNC automation equipment.

- Customizable Hand Controller Buttons: You can assign functions you want to the buttons on the hand controller provided by the RB Series. Perform simple tasks without the need for additional button creation.

- DataBase: It has its own built-in database system, so it can store various data.

Plug-and-Play Accessories

RB series cobots support “Plug&Play” for easier integration of a variety of peripherals.

The streamlined approach accelerates the development process of versatile solutions that are compatible with diverse working conditions.