Task

Almost every car steering wheel has control knobs and buttons attached to it, which are connected to the central control. This requires very thin cables that are integrated inside the steering wheel. For the manufacture of such cables, our customer relies on robots and vision. In a manner of speaking, the vision system is the seeing eye of the robot. With a single handle, ribbon cable is picked, repositioned, stamped, checked and welded. Correct repositioning in the same process step.

Customer Benefits

- Adaptation to new ribbon cable types within minutes

- Quality control integrated into the manufacturing process

- No processing of bad parts

Goods and Services Provided by Compar AG

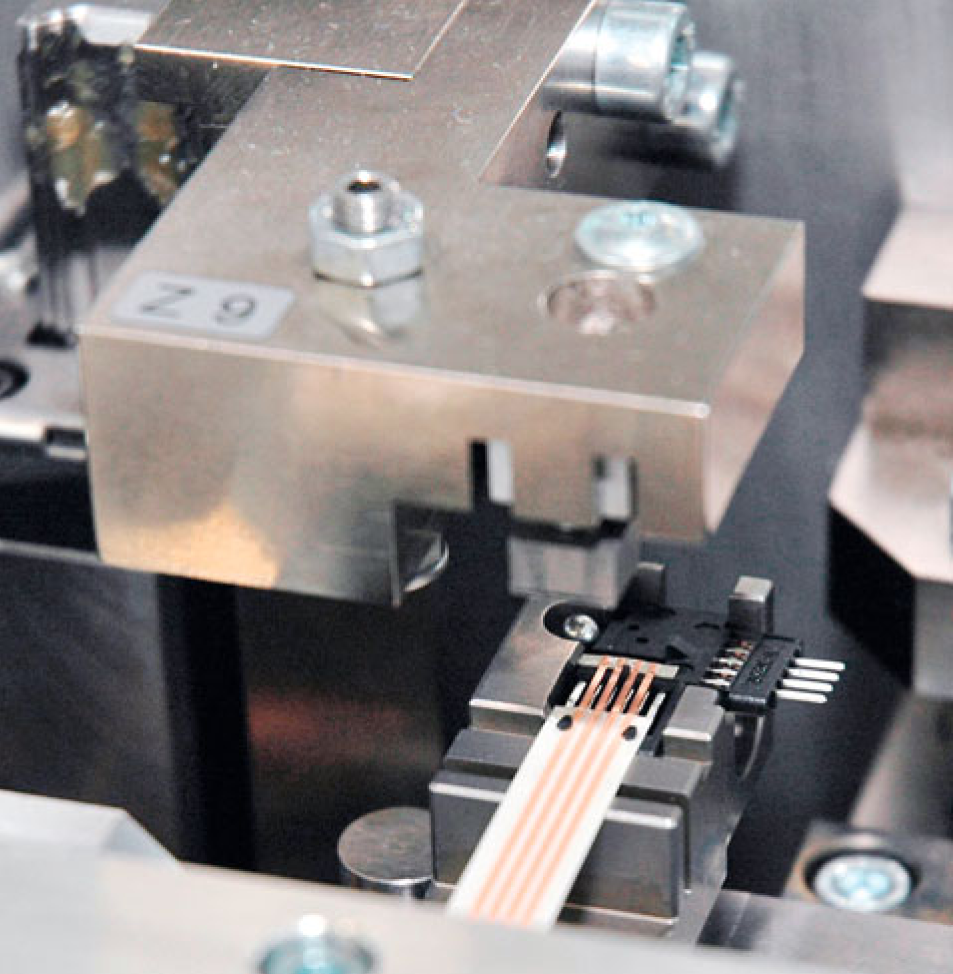

This solution is based on a camera-guided robot system. Using an Epson SCARA robot and a vision system, the ribbon cables are measured and adjusted. First, the robot receives the pre-positioned ribbon cable from the tool carrier and moves below the vision station with the ribbon cable. Here, the exact position is determined, in consideration of the copper conductors in the ribbon cable. X and Y-coordinates, including the rotation angle, are transferred to the robot; they are used to calculate the exact stamping position to be approached and the cable is repositioned. After the stamping has been completed, the robot moves back via the vision station and the ribbon cable is subjected to an optical control. Once the inspection has been completed successfully, the cable is inserted into the sensor head and welded.

Products Used

Intelligent Camera, Epson SCARA robot, Image acquisition station