From the smallest scratches, dents and injuries to aesthetic contaminations, stains and discolourations on the surface, Compar surface inspection systems ensure flawless end-user products

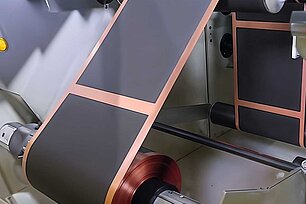

Surface inspection is used to check surfaces for dents, scratches, irregularities, discolouration or other deviations. These are not only functionally relevant but also aesthetic defect inspections.

On the one hand, classical 2D methods can be used to examine pronounced defects such as soiling, discolouration, indentations, gloss levels as well as three-dimensional defects with loss of their height or depth profiles, as long as they can be represented in 2D space with high contrast.

On the other hand, there are numerous 3D process methods that are used to record the geometric spatial surface condition. Such optical 3D inspection systems have high resolutions down to the nanometre range, which also includes three-dimensional defect sizes and thus allows defect detection.

Coloured, patterned, transparent, reflective and mirroring surfaces can be inspected with industrial image processing. Compar AG has an extensive collection of smart surface algorithms for 2D and 3D detection, summarised as a surface/cosmetic inspection module which is a main component of the integrated VISIONexpert® image processing software. Based on the customer's requirements, the appropriate algorithms for the solution are determined, tested and finally applied.

Defect-free surface

Robust inspection of smallest surfaces, defects on metal, plastic and glass.

Ease of use

Fast and simple production-accompanying training routines for new products. Short changeover times between different products.

Degrees of freedom and flexibility

Surfaces can be inspected with 2D cameras or with 3D scanners. Depending on the quality control requirements, "Deep Learning" algorithms are also used in addition to the classic inspection method to achieve the best results.