Secure Track & Trace: Our focus

Compar concentrates on turn-key solutions for Level 1 and 2 with interfaces to Level 3 and 4.

For Level 1, we deliver reliable devices for code reading and image processing.

For Level 2, we deliver central management stations based on VISIONexpert®. By means of this proven platform code readers, camera stations and printing devices are controlled comfortably for the whole production line. The configuration can be configured per product type according to the customer requirements.

Communication between Level 1 and Level 2 is realized by interfaces which are standard in industry like digital I/O, Ethernet TCP/IP, Profinet or some field bus systems.

For communication with Level 3 and Level 4, standard interfaces are available as XML for product management

Why ST&T?

The main goal of Secure Track & Trace, or ST&T in short, is to prevent the sale of counterfeit drugs on the market place, which could be harmful to patient health. For this purpose, the EU directive Falsified Medicines Directive 2011/62/EU has been put into force. These directives must be implemented within 3 years. Starting in 2017 each package of prescription drugs in the European Union should be marked with unique security features, allowing products to be traced back to manufacturers, distributors and product data. The regulations allow for some variations, but lot number, serial number, manufacturer information and expiry date have to be coded in a 2D DataMatrix code on the packaging. For full traceability, aggregation data must also be recorded and archived. For further information on the data to be collected, transmitted and archived refer to the EPCIS (Electronic Product Code Information Services) standard developed by GS1.

Our Services / Our Solution

We offer complete solutions for ST&T Level 1 & 2:

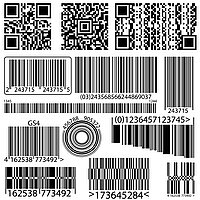

- With code readers, smart cameras as well as PC-based systems for reading 2D DM code, linear barcode, RSS code, EAN code etc.

- Verifier systems for off-line verification according to ISO 15415 as well as validation for GS1 conformity of 2D DM code.

Central management for:

- Configuration and control of camera stations

- Product definition, storage and loading of jobs

- Generation of records / audit trails

- Communication with Level 3 and 4 software

- Turn-key solutions

- Documentation, test plans, validation support etc.

Product Management

Product management consists of:

- Definition of new products

- Loading of product data on the production line

The central management station allows:

- Configuration and control of devices on the production line

- Definition of the GS1 information to be used

- Set-up of tests and inspection tasks (position and size, font, color, etc..)

- Activation and deactivation of individual tests

- Format of OCV/OCR and code information

- Extended or additional inspection

The Compar solution is 21 CFR Part 11 compliant and can be validated following the procedures laid down in GAMP 5. User management and traceability fulfill all relevant requirements and audit trails can be generated from the central management station.

Our standard platform VISIONexpert® can be validated efficiently, but customer specific modules may require additional effort.

Compar can support you in the validation process.