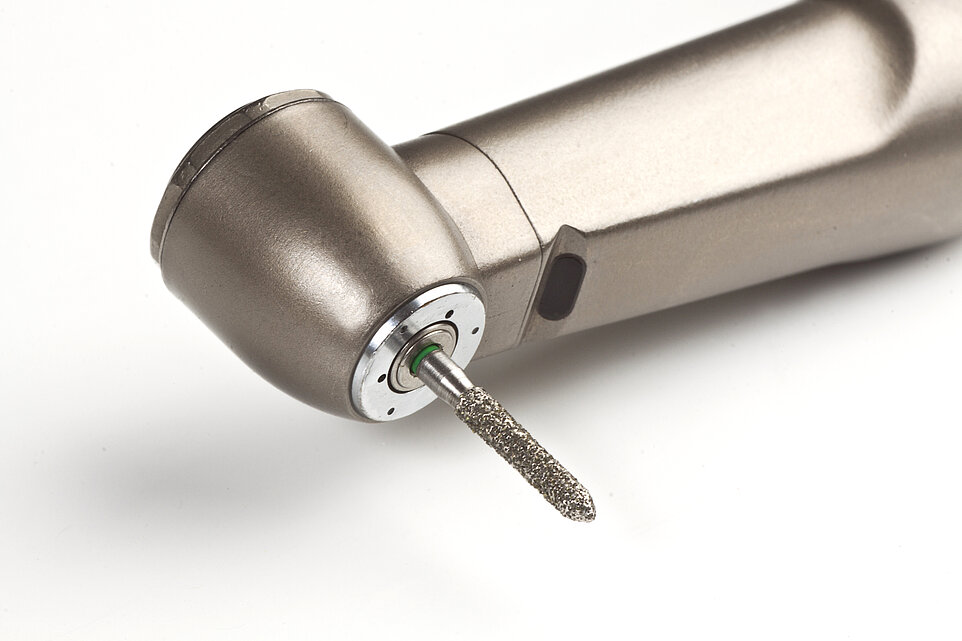

Task

The task is to provide precision parts for dental drills, which are available as bulk goods, in pallets for the subsequent process. To do so, our universal palletising system was employed. This palletising cell consists of only three main components – feeder, robot and image processing unit. After filling the pallets with parts, the palletising system operates completely autonomously. It handles not just one, but up to 15 part types. There are up to 5 pallet types that are used for palletising. During the autonomous operation, resources can be employed for other tasks.

Customer Benefit

- Verification of the parts' shape and dimensional accuracy is carried out via automated optical inspection.

- Safeguarding of single-type products for the subsequent process.

- No bad parts are processed further unnecessarily.

- Safeguarding of process compliance for parts with increasing batch sizes

Goods and Services Provided by Compar AG

We have supplied a complete palletising system (cell design), consisting of a mechanical cell, a robot, a feeder and an image processing system. In addition, the entire control system is implemented using our VISIONexpert® platform.

Products Used

VISIONexpert®, Anyfeeder, Epson SCARA robot, AIS cell