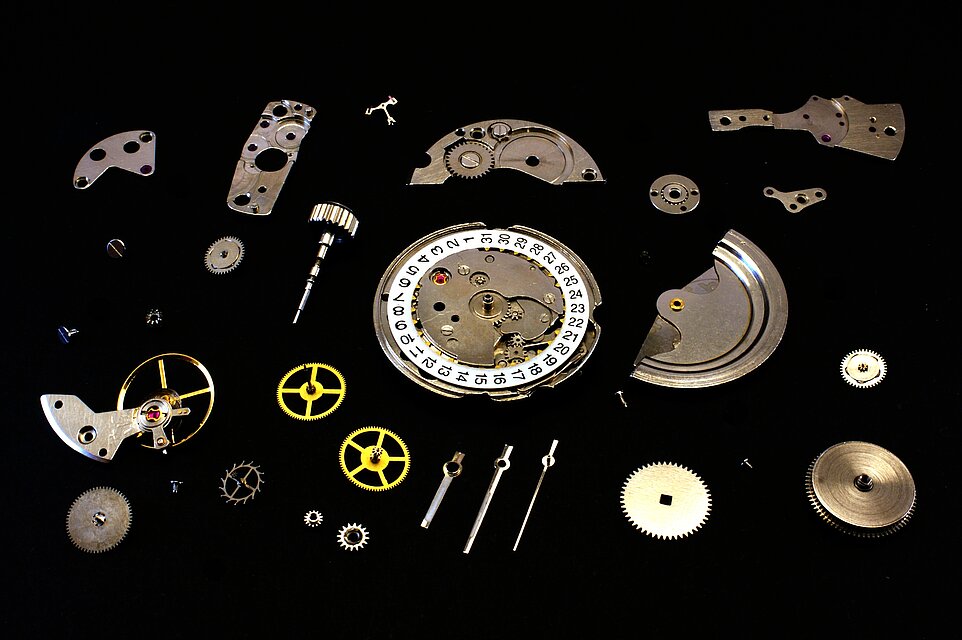

Task

Whether for lubricating, assembling or printing of watch parts - our flexible handling system is used by well-known manufacturers of watch components. The supply as bulk goods and the removal as products provided in a blister pack constitutes a task ideally suited for our handling system. Even the sequence of the handling process can be changed for other inspections. For instance, the system can be switched from removal to supply as a blister pack. The handling consists of two components that represent the perfect combination – vision system, and robot. Increasing the level of automation.

Customer Benefit

- Increase the degree of automation

- Using resources for higher-level tasks

Goods and Services Provided by Compar AG

For our clients, we have decided on pairing Epson SCARA with VISIONexpert®, which provides the required flexibility. In addition, the image processing system takes on the task of calculating the exact position for high-precision picking. The set-down positions achieved by our solutions are in the micrometre range and completely meet the requirements of the watch making industry. Due to the configurable VISIONexpert® software, any adjustments with respect to parts positioning, quality control and a check for presence are implemented quickly on site.

Products Used

Epson SCARA Robot, VISIONexpert®, Feeder