Easy Teach-In mechanism convinces customer

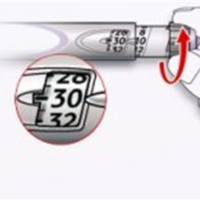

The dosage graduation of insulin injectors has to meet high demands with respect to print quality and positioning. In order to ensure this, each and every part is inspected by means of a vision system. Due to the complexity of inspection and image acquisition, a VISIONexpert® PC-based image processing system is deployed in combination with the CVL image processing library including the PatMax family of algorithms from Cognex.

A line scan camera, which generates an unwrapped view of the cylindrical surface, serves to realize the image acquisition. For the print’s subsequent inspection, reference images of certified good products are used. As the printing may vary depending on color consistency, the tampon’s temperature, and other parameters, in-line re-teaching is indispensable. The user has to be provided with adjustment tools which allow for accepting or rejecting specifi c adjustments in the re-teaching process.

The advantages of a solution including VISIONexpert®

- Line scan camera system; 2000 x 1400 pixels per image

- Teaching with several master samples

- Numerous parameters (tampon is "flexible")

- Visualization for re-teaching means: simple user interface but sophisticated programming

- User administration; authorization levels providing for various access options

- Traceability of system settings, test parameters, and measuring results (21 CRF Part 11)